Seems like ages ago when Eric took Labor Day week off to build the side porch. With the false optimism that accompanies every new project, he expected that he could demolish the old porch and build the new one, right up through framing, decking, railings, and corner posts … leaving the siding for a couple of late-summer weekends.

Well … you know how that goes. Demolition, spider control, and site prep took that entire first week. By the end of September, the frame was up. Then we had the wettest October on record and progress stalled. We even left the country to avoid doing any porch work. Just when the weather showed signs of cooperating, Eric was sent to St. Louis to work for a week. Let’s see … that puts us about seven weeks behind schedule. Not as bad as Seattle’s Alaskan Way tunnel project, but, as I look out onto our soggy November streetscape, more discouraging because it’s our house.

We became even more discouraged when we set out to buy porch flooring material. A couple of years ago we discovered Azek porch boards at the home show. These 3-inch composite tongue-and-groove boards look identical to our original front porch floor.

We couldn’t wait to use them at our house, and finally, the time had come. That is, until we priced them. Each 16-foot board cost $67.36. We needed 60 boards … so that would be over $4000.00 just for the porch floor (not including fasteners). We couldn’t see spending that much. Is this house worth $4K in porch flooring? My heart said “yes,” but my head said, “No way!!” It simply didn’t pencil out.

Plan B: Trex porch boards, which were slightly, but not much, cheaper. These companies are pretty damned proud of their porch boards.

Plan C: Use what would have been used in 1913—cedar decking. I like the idea of using period-correct materials (I also liked the idea of the Azek boards because they were so convincing and they would never rot). However, if they’re properly treated with an oil-base stain, cedar boards should last for decades … long after we move out and into an old-folks’ home. We searched for classic 3-inch tongue-and-groove cedar porch boards … but we came up empty-handed.

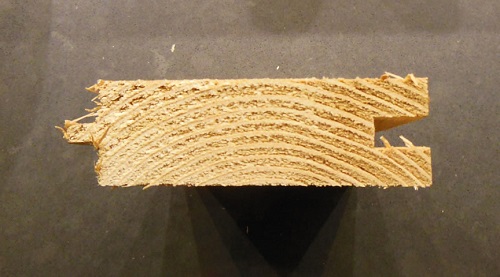

Okay … Plan D: Buy ubiquitous 5/4 cedar decking, at $9.98 per 16-foot board, or $600.00 total. This decking has radius corners, a look we definitely didn’t want, but Eric was game for trimming these boards down and milling his own tongue-and-groove porch boards! As luck would have it, his table saw motor burned out. Hey, that’s not a bad thing! That’s a tool-buying opportunity (TBO)! The new saw was only $230. (Remember how much we’re saving by not using Azek.) Let the milling begin!

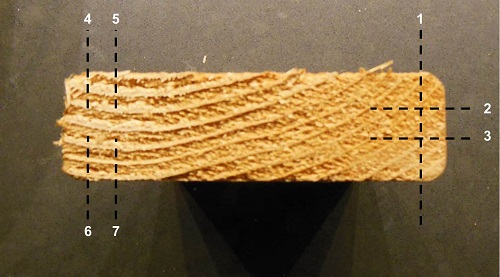

Another optimistic estimate—milling should take about 8 hours. Each board needed seven cuts to achieve the tongue-and-groove profile.

Eric spent at least 16 hours patiently milling the boards (and making mounds of sawdust) over the course of two weekends. He reminded me again how much money we were saving over the Azek. The boards then patiently waited in the rain for his return from St. Louis.

Now, to attach those boards and make an actual porch out of them! Eric needed a dry day and a rental angle flooring stapler. We had a hard time finding either. His brief window of dry weather was running out, and the rental staplers at Home Depot didn’t shoot long enough staples for his boards. This was not a tragedy—this was another TBO! He came home with his own angle flooring stapler … so he was able to wait out the bad weather. Add $170 to the flooring total, bringing it to $1000, which is a whole lot better than $4000.

Once Eric began stapling the boards, the operation went pretty fast. He even let me use the stapler for a bit. It was fun—like playing whack-a-mole. However, even whack-a-mole gets old when you have to bang in five staples on each of 120 boards. In one weekend, “suddenly” we had a porch floor, and it looks great! Duke approves, too.

The next step is sanding … and building the railings. But November is storm season in the Pacific Northwest. Will we get a break in the weather? Will we have a finished porch by summer? Will another TBO come Eric’s way? Stay tuned …

Personally milled boards- that is dedication! As long as it is done by next summer, it’s good, right? By the way, Eric is amazing- great carpenter and takes beautiful photographs!

He really IS amazing! None of our projects could happen without him!!

This project looks sooooo great. Custom, period, slick. This project has bragging rights for sure. I guess the faux deck makers charge a lot because you’ll never have to replace it unless you want to change the color. Jo @ Let’s Face the Music

Thanks, Jo! It even looks great in our 25 degree weather–brrr!

Lucky for you, this weekend will be sunny! The boards look so nice and Eric did a great job!

D’Arcy,

First of all, you are one lucky lady to be married to such a talented guy. The deck looks great and I’m sure, based on the reports of how you two do projects, that this decking will be fabulous and weather proof. I can tell you, Mr. B would be thrilled at the prospect of buying any new power tool required to do anything around the house. 🙂

Stay dry this weekend.

xo

Karen

I really am super-lucky, Karen. Without Eric none of this could happen (and I would have no blog!)!! We are in more danger of freezing to death this weekend than getting wet. Sigh … 🙂

I was shocked by how expensive deck boards were last summer when we replaced our front porch. 😦 You’rs is going to look great though!

Incredible, isn’t it? “Remember how much we saved” has become a running joke whenever we spend $$ on something else!